+91 8758687144

Pulpers have a major impact on the downstream stock prepa-ration processes. The purpose of the pulping process is to pulp the suspension to the best possible degree while remov-ing a large amount of contaminants. At the same time, low energy consumption and low wear are necessary for an effi-cient pulping process. In addition, a stable ragger formation helps ensure a smooth production process.

With IntensaPulper IP-RRK we have developed a pulper, which offers highly energy-efficient pulping of recovered paper at greater pulping consistency and higher pulping quality.

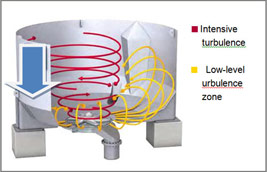

The flow-optimized vat design, combined with the eccen-trically arranged rotor and baffle, produces a zone intensive turbulence*. This results in improved mixing of the stock and faster bale submergence.

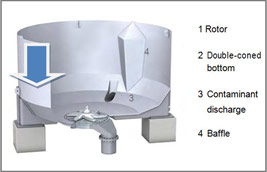

At the same time, the lower-level turbulence in the rest of the vat allows the recovered paper to swell and promotes energy-efficient defibering.* The double-coned bottom creates a flow-optimized transition of the stock from the bottom of the pulp-er to the cylindrical vat wall.

The specially developed rotor shape achieves extremely reliable ragger operation. It ensures that the number of ragger breaks can be reduced to once a month. A reliable sealing mechanism and stable drive design reduce main-tenance intervals to a minimum.

The double-coned bottom combined with the baffle directs the coarse contaminants towards the reject discharge. In IntensaPulper IP-RRK this allows reliable removal of the coarse heavy contaminants in the Junkomat or Junk Tower and transfer of the coarse light contaminants to RRK's IntensaMaXX pulper detrashing machine.

Thanks to its high energy savings IntensaPulper IP-RRK is part of our new BlueLine product range. With BlueLine, customers profit from proven RRK quality and reliability and at the same time low energy, fiber, water and maintenance costs.